Duration: 4 days

For: All maintenance engineers and technicians

This course is designed for Technicians and Engineers with limited experience in Vibration measurement and analysis. It is designed to provide the attendees with:

Course Contents:

Duration: 5 days

For: All maintenance engineers and technicians

Basic Machinery Vibrations is designed as an introductory course to the use and analysis of machinery vibration data for condition monitoring.

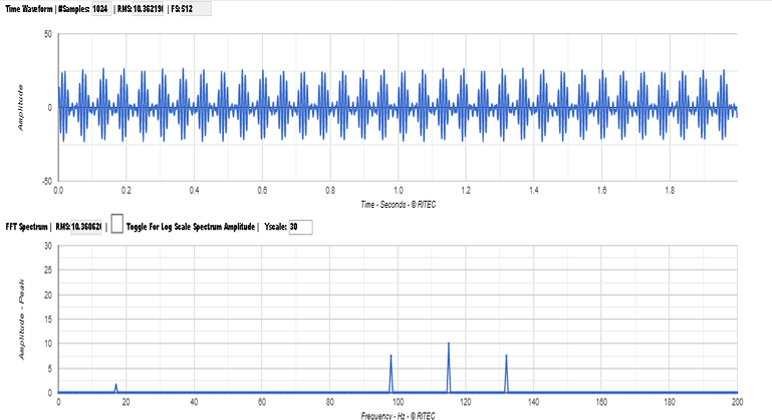

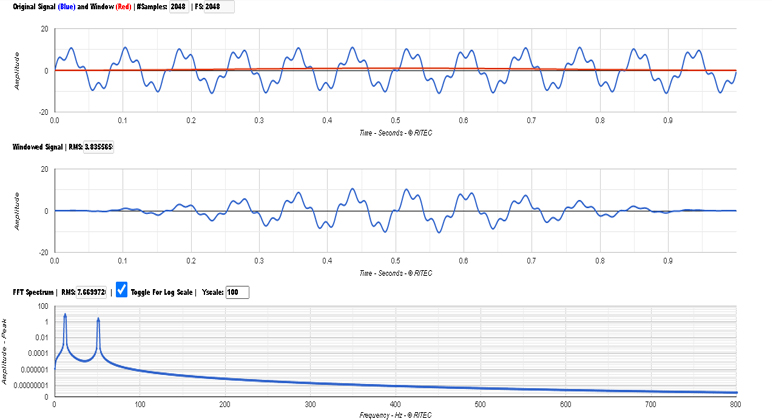

The course emphasizes the effects of vibration on mechanical equipment, the instrumentation used to measure vibration, the techniques used for vibration analysis and control, developing a condition monitoring program, and vibration correction and criteria. Examples and case histories of Industrial vibration problems are used to illustrate techniques.

Participants have the opportunity to become familiar with these techniques during workshops. This course will be of interest to engineers and technicians who must identify and correct faults in machinery; and should be sufficient in addition to field experience, to prepare the attendees for the Vibration Analyst - Category II Certification Exam.

Course Contents:

Duration: 5 days

For: All maintenance and vibration engineers and technicians

The most widely accepted measure of machine condition is its vibration signature. This course is designed to expose the techniques of vibration analysis of machinery, with the aim of improving machinery monitoring and diagnosis.

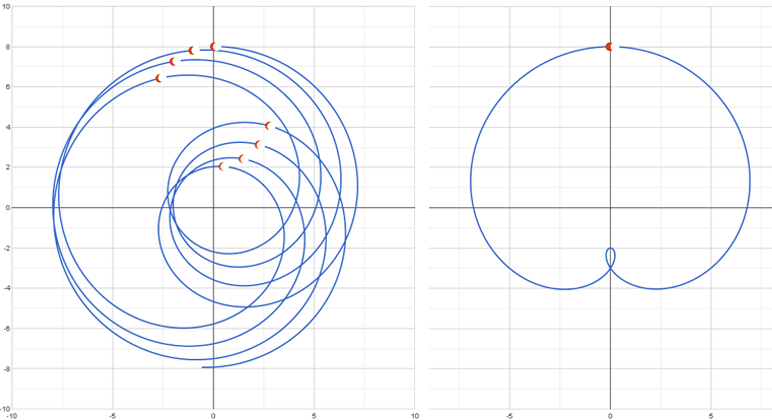

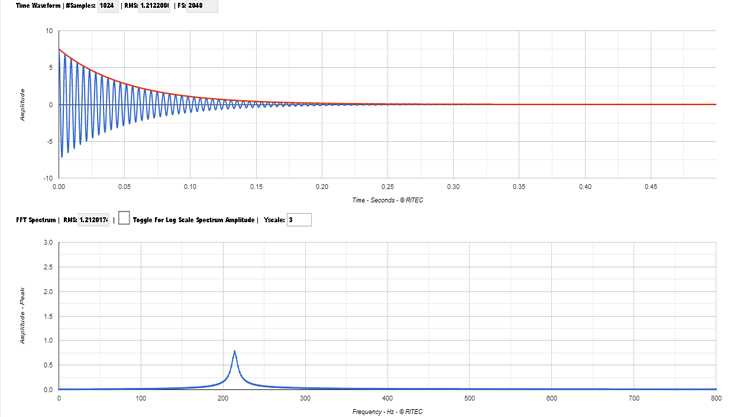

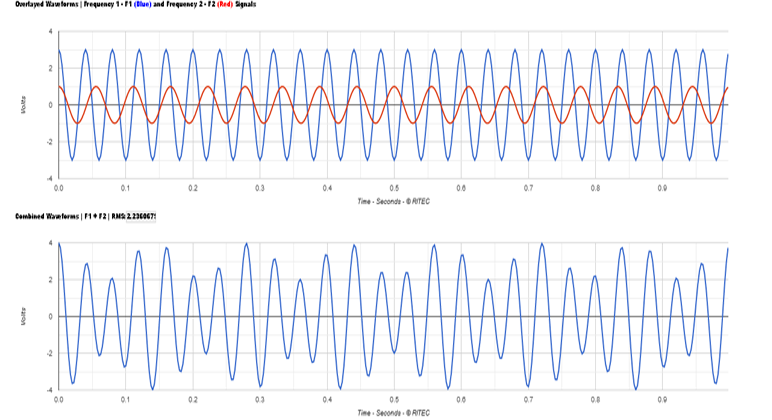

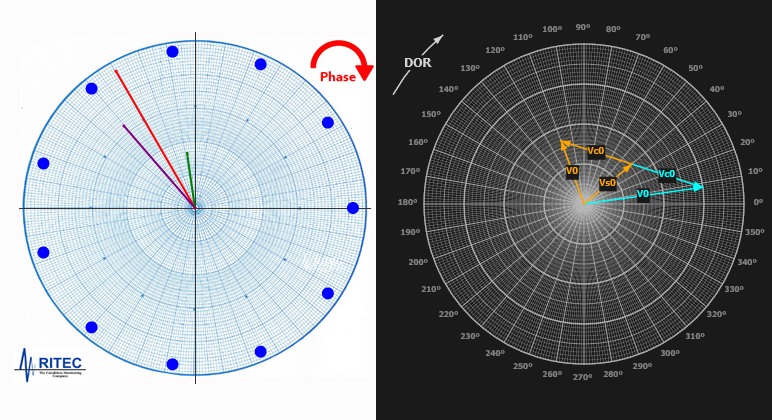

This course is a more advanced course with emphasis on diagnostics techniques. Not only spectrum analysis, but also time domain, phase analysis and demodulation techniques are discussed. The emphasis is on techniques to verify the existence and the extent of faults and means to evaluate the condition of a machine. Bearing Faults, Gear Box Faults, Electric Motor Vibrations, and Rotating Machinery Malfunction, Balancing, Isolation and Correction represent the main thrust of this course.

The course provides a unique format in which an abundance of case studies are presented as application of machine condition analysis. The course prepares attendees for Category III certification according to ISO 18436.

Course Contents:

Duration: 5 days

For: All maintenance and vibration engineers

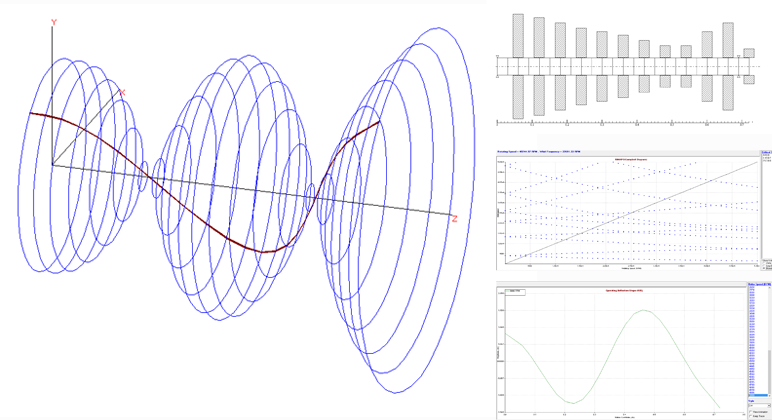

Rotordynamics describes the science and practice of analyzing the dynamics of rotating machinery. All rotating machinery, particularly high speed-high performance machinery, inherently exhibit unique dynamical behavior that can affect the operation and maintenance of the machine.

This course describes the fundamentals of the dynamics of rotors and the analysis and correction of rotating machinery problems. Topics include:

Course Contents:

Duration: 5 days

For: All maintenance and vibration engineers

This course is intended to stress the relationship between structural and machinery vibration. Topics covered include:

Course Contents:

Duration: 4 days

For: All maintenance and vibration engineers and technicians.

This is the same as the Basic Machinery Vibrations (BMV) course but with selective hands on workshops to provide practical training on machinery vibration.

The course emphasizes the effects of vibration on mechanical equipment, the instrumentation used to measure vibration, the techniques used for vibration analysis and control, developing a condition monitoring program, and vibration correction and criteria. Examples and case histories of Industrial vibration problems are used to illustrate techniques.

Participants have the opportunity to become familiar with these techniques during workshops. This course will be of interest to engineers and technicians who must identify and correct faults in machinery; and should be sufficient in addition to field experience, to prepare the attendees for the Vibration Analyst - Category II Certification Exam.

Course Contents:

Duration: 3 days

For: All maintenance and vibration engineers

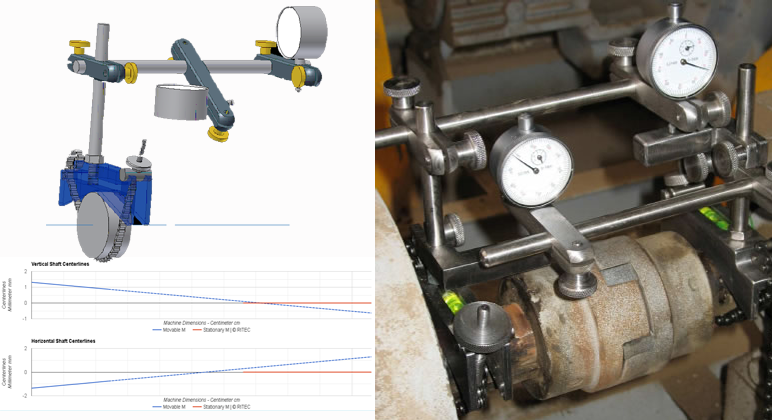

Unbalance is the most common machinery faults. This course introduces techniques to identify unbalance from vibration measurement data. Moreover, the course introduces the techniques for the corrective maintenance actions of balancing.

This course is intended to provide basics of balancing of rotating machinery and field applications. The course presents the vibration analysis leading to the identification of unbalance of rotating machines. For balancing the course presents field balancing techniques including single plane balancing, two-plane balancing and static-couple balancing. Workshop applications will be provided.

The course provides a unique format in which an abundance of case studies are presented. Workshop sessions are conducted daily to illustrate the techniques of balancing and alignment, as well as the tools and software used.

Vibration Institute and RITEC courses are designed to provide the attendees with theory, techniques, and procedures as well as practical case histories that illustrate ways to analyze various types of equipment. In-class demonstrations and workshops will help in learning the methods used to solve balancing problems.

Course Contents:

Duration: 3 days

For: All maintenance and vibration engineers

The course presents various alignment methods including

Course Contents:

RITEC is pleased to offer any of its training courses as in-house courses for requesting customers. We offer a blend of our standard courses, as well as customized training programs in Condition Monitoring and Machinery Vibration Analysis, to fit our customer's needs.

All in-house courses are to be held at Customer site for about 15 engineers or technicians. It is understood that Customer shall provide transportation (Business Class travel) to and from site, and accommodation on-site for instructors.

All our courses are offered as Vibration Institute courses. The course certificates are issued from the Vibration Institute, the training materials are all from the Vibration Institute, and even the course transparencies are mostly from the Vibration Institute. This assures the quality of the course as conforming to the international level of training. In addition, the course instructors are Certified Vibration Specialists, which ensures practical knowledge of the art and science of vibration analysis.

The courses will be taught by a group of instructors led by Dr. Aly El-Shafei, Professor at Cairo University and General Manager of RITEC. In addition to being Professor at Cairo University, Dr. Aly El-Shafei is also a consultant to industry, and has cooperated with such companies as General Electric (USA), Assix International (USA), Mannesmann Demag (Germany), MTU (Germany), SUCO, BAPETCO and AOI (Egypt). In addition, Dr. El-Shafei is involved in several local and international research projects. He has published many technical papers in the vibration field, and holds two patents to his name. Dr. El-Shafei holds a Ph.D. from the Massachusetts Institute of Technology. He is a member of ASME, Tau Beta Pi, and Sigma Xi, and is a Certified Vibration Analyst - Category IV.

As is generally known, all specialized trades that can affect a company’s safety and performance are Certified, e.g. welders and inspectors.

Recently, there has been a worldwide trend towards Certifying Vibration Specialists. This move started in the United States, and was pioneered by several Chemical Processing and Oil Companies requesting the certification of their Vibration Specialists to assure their competence in the field, with expected rewards to the company performance and safety record

The Vibration Institute has established a world-wide Certification program in accordance with ISO 18346 where four categories of Vibration Analysts are currently recognized:

RITEC is pleased to announce that the Vibration Institute Certification exams are conducted regularly in: Cairo, KSA, & UAE area each year.

| ISO Category 1* | ISO Category 2* | ISO Category 3* | ISO Category 4* | |

|---|---|---|---|---|

| Exam Fees | $ 350 | $ 400 | $ 450 | $ 500 |

| Service Fees | $ 290 | $ 300 | $ 310 | $ 320 |

| Total | $ 640** | $ 700** | $ 760** | $ 820** |

Certification Requirements

The Process:

Category I Vibration Analysts are qualified to perform a range of single channel machinery vibration condition monitoring and diagnostic activities including data acquisition on predetermined routes, machine steady state testing to predefined procedures, and comparison of readings against pre-established alert settings.

Minimum Recommended Experience: 6 months

Minimum Training Hours: 30 hours

Requirements: Introduction to Machinery Vibrations – CAT I

Category II Vibration Analysts are qualified to perform basic vibration analysis using single-channel instruments according to established procedures, set-up instruments, and maintain a database of results.

Minimum Recommended Experience: 18 months

Minimum Training Hours: 60 hours (38 hours + VI Category I)

Requirements: Basic Machinery Vibrations – CAT II

Category III Vibration Analysts are qualified to establish, direct, and\or perform programs for condition monitoring and diagnostics of machines including spectral, waveform, and orbit analysis. Category III certified Vibration Analysts shall be qualified to perform minor corrective actions involving operating deflection shapes, single-plane balancing, and diagnostic testing..

Minimum Recommended Experience: 36 months

Minimum Training Hours: 90 hours (38 hours + VI Category II)

Requirements: Machinery Vibration Analysis – CAT III

Category IV Vibration Analysts are individuals who understand the theory of mechanical vibrations, advanced vibration analysis techniques and signal analysis. They shall be qualified to direct condition monitoring programs, perform major diagnostic efforts, and perform and recommend corrective actions and design modifications.

Minimum Recommended Experience: 60 months

Minimum Training Hours: 130 hours (64 hours + VI Categories III)

Requirements:

| Upcoming Vibration Institute ISO 18436 Courses | Certification Examinations for CAT I-IV | Training Venue |

|---|---|---|

| ISO Category I – Introduction to Machinery Vibration (IMV) |

Examination Session CAT I-II-III-IV January 12th – 15th, 2026 |

Dual Classroom and Online |

| ISO Category II – Basic Machinery Vibration (BMV) |

Examination Session CAT I-II-III-IV February 8th – 12th, 2026 |

Dual Classroom and Online |

| ISO Category III – Machinery Vibration Analysis (MVA) |

Examination Session CAT I-II-III-IV April 19th – 23rd, 2026 |

Dual Classroom and Online |

| Rotordynamics & Balancing |

Examination Session CAT I-II-III-IV May 18th – 21st, 2026 |

Dual Classroom and Online |

| Alignment |

Examination Session CAT I-II-III-IV July 7th – 9th, 2026 |

Dual Classroom and Online |

| ISO Category I – Introduction to Machinery Vibration (IMV) |

Examination Session CAT I-II-III-IV August 3rd – 6th, 2026 |

Dual Classroom and Online |

| ISO Category II – Basic Machinery Vibration (BMV) |

Examination Session CAT I-II-III-IV September 20th – 24th, 2026 |

Dual Classroom and Online |

| ISO Category III – Machinery Vibration Analysis (MVA) |

Examination Session CAT I-II-III-IV October 18th – 22nd, 2026 |

Dual Classroom and Online |

| Structural and Machinery Vibration |

Examination Session CAT I-II-III-IV December 14th – 17th, 2026 |

Dual Classroom and Online |